-

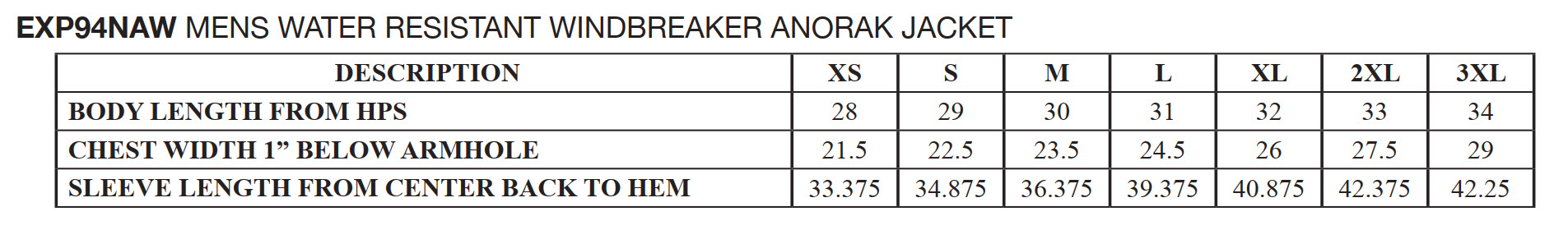

WATER RESISTANT WINDBREAKER ANORAK JACKET

Click here to download Spec Sheet This Nylon Water Resistant Windbreaker Anorak Jacket is screen print friendly, and has waterproof nylon fabric. The Nylon exterior fabric is coated with a 100% water proof coating... however, we give this jacket a Water Resistant rating since the seams are not waterproofed, which may allow water to eventually enter through the seams when exposed for extended periods of time in a downpour. 100% nylon 330D with Interior PU waterproof coating Nylon Outer Shell: Waterproof Coating = Level 3 Inner PU Coating: Breathability/Permeability = 5,000 Water Pressure Resistance = 10,000 mm DTM neck taping tear away neck label #5 DTM body coil zipper matte metal zipper pull rubber zipper pull tab zipper garage fine mesh hood liner matte nickel metal eyelets 3 panel hood scuba neck round poly drawstring hidden snaps inside front pocket flap side slit pockets tightening toggle at waistband elastic cuffsLogin to see prices Please Note: Printing Notes:

Use a nylon or plastisol ink with a catalyst (hardener). Certain Poly Inks can work as well. Ask your ink supplier. Keep in mind a catalyst will shorten the shelf life of the ink leaving left over ink unusable as it will harden.

Use tight screens with 200+ mesh count to lay down a little less ink than would be used on tees (tees normally use a more open mesh like a 110). Ink tends to sit on top of the surface of this fabric as opposed to pressing into cotton type fabrics. A harder squeegee can help lay down less ink and help keep cleaner design edges.

Nylon fabric also tends to move more than tees on the printing pallet. Sometimes a jacket clamp is recommended when doing multi-color prints.

Curing time and temperature will vary by ink types used on nylon fabrics. VERY IMPORTANT to cure your ink at the right temperature without burning or shrinking nylon. Nylon fabrics should usually be cured at temperatures under 320. Flash at low temperatures to keep from burning and/or shrinking fabric. (consult ink supplier and test).

Washing the printed sample garment(s) after 24+ hours (so hardener has set) is recommended to make sure you have proper curing and ink adhesion.

*ALWAYS consult your ink supplier for the right ink, cure temperatures, and curing time. Then run your own test sample(s)

Please Note: Printing Notes:

Use a nylon or plastisol ink with a catalyst (hardener). Certain Poly Inks can work as well. Ask your ink supplier. Keep in mind a catalyst will shorten the shelf life of the ink leaving left over ink unusable as it will harden.

Use tight screens with 200+ mesh count to lay down a little less ink than would be used on tees (tees normally use a more open mesh like a 110). Ink tends to sit on top of the surface of this fabric as opposed to pressing into cotton type fabrics. A harder squeegee can help lay down less ink and help keep cleaner design edges.

Nylon fabric also tends to move more than tees on the printing pallet. Sometimes a jacket clamp is recommended when doing multi-color prints.

Curing time and temperature will vary by ink types used on nylon fabrics. VERY IMPORTANT to cure your ink at the right temperature without burning or shrinking nylon. Nylon fabrics should usually be cured at temperatures under 320. Flash at low temperatures to keep from burning and/or shrinking fabric. (consult ink supplier and test).

Washing the printed sample garment(s) after 24+ hours (so hardener has set) is recommended to make sure you have proper curing and ink adhesion.

*ALWAYS consult your ink supplier for the right ink, cure temperatures, and curing time. Then run your own test sample(s) -

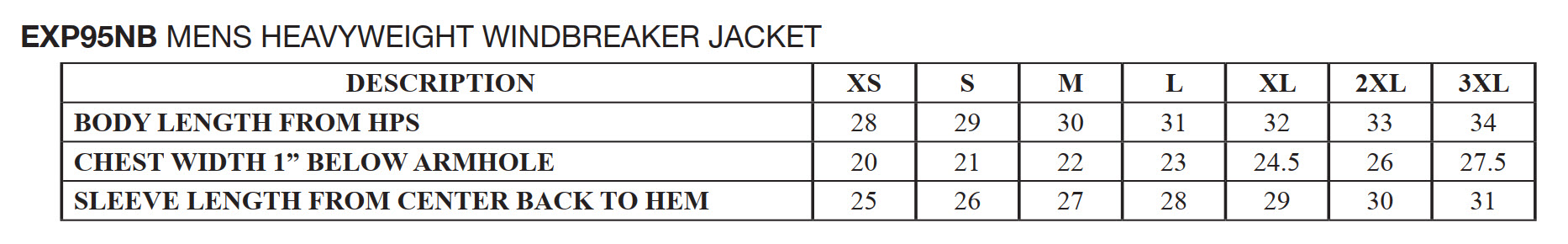

WATER RESISTANT HOODED WINDBREAKER COACHES JACKET

Click here to download Spec Sheet This Nylon Windbreaker Coaches Jacket is screen print friendly, and has waterproof nylon fabric with snap front closure. The Nylon exterior fabric is coated with a 100% water proof coating... however, we give this jacket a Water Resistant rating since the seams are not waterproofed, which may allow water to eventually enter through the seams when exposed for extended periods of time in a downpour. 100% nylon 330D with Interior PU waterproof coating Nylon Outer Shell: Waterproof Coating = Level 3 Inner PU Coating: Breath-ability/Permeability = 5,000 Water Pressure Resistance = 10,000 mm unlined hood self neck tape tear away neck label antique brass eyelets (black/black color = matte black metal eyelets) antique brass 6 snap front closure (black/black color = matte black metal snaps) elastic cuffs underarm grommets drawcord closure at hood and bottom opening standard fitLogin to see prices Please Note: Printing Notes:

Use a nylon or plastisol ink with a catalyst (hardener). Certain Poly Inks can work as well. Ask your ink supplier. Keep in mind a catalyst will shorten the shelf life of the ink leaving left over ink unusable as it will harden.

Use tight screens with 200+ mesh count to lay down a little less ink than would be used on tees (tees normally use a more open mesh like a 110). Ink tends to sit on top of the surface of this fabric as opposed to pressing into cotton type fabrics. A harder squeegee can help lay down less ink and help keep cleaner design edges.

Nylon fabric also tends to move more than tees on the printing pallet. Sometimes a jacket clamp is recommended when doing multi-color prints.

Curing time and temperature will vary by ink types used on nylon fabrics. VERY IMPORTANT to cure your ink at the right temperature without burning or shrinking nylon. Nylon fabrics should usually be cured at temperatures under 320. Flash at low temperatures to keep from burning and/or shrinking fabric. (consult ink supplier and test).

Washing the printed sample garment(s) after 24+ hours (so hardener has set) is recommended to make sure you have proper curing and ink adhesion.

*ALWAYS consult your ink supplier for the right ink, cure temperatures, and curing time. Then run your own test sample(s)

Please Note: Printing Notes:

Use a nylon or plastisol ink with a catalyst (hardener). Certain Poly Inks can work as well. Ask your ink supplier. Keep in mind a catalyst will shorten the shelf life of the ink leaving left over ink unusable as it will harden.

Use tight screens with 200+ mesh count to lay down a little less ink than would be used on tees (tees normally use a more open mesh like a 110). Ink tends to sit on top of the surface of this fabric as opposed to pressing into cotton type fabrics. A harder squeegee can help lay down less ink and help keep cleaner design edges.

Nylon fabric also tends to move more than tees on the printing pallet. Sometimes a jacket clamp is recommended when doing multi-color prints.

Curing time and temperature will vary by ink types used on nylon fabrics. VERY IMPORTANT to cure your ink at the right temperature without burning or shrinking nylon. Nylon fabrics should usually be cured at temperatures under 320. Flash at low temperatures to keep from burning and/or shrinking fabric. (consult ink supplier and test).

Washing the printed sample garment(s) after 24+ hours (so hardener has set) is recommended to make sure you have proper curing and ink adhesion.

*ALWAYS consult your ink supplier for the right ink, cure temperatures, and curing time. Then run your own test sample(s) -

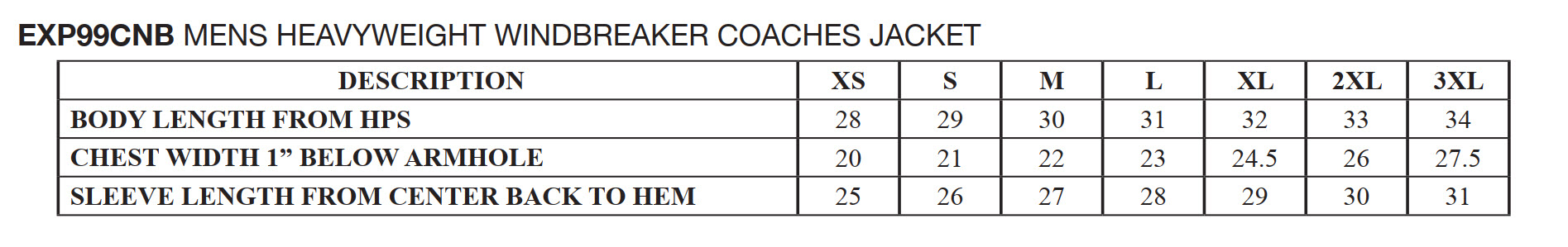

WATER RESISTANT WINDBREAKER COACHES JACKET

Click here to download Spec Sheet This Nylon Windbreaker Coaches Jacket is screen print friendly, and has waterproof nylon fabric with snap front closure. The Nylon exterior fabric is coated with a 100% water proof coating... however, we give this jacket a Water Resistant rating since the seams are not waterproofed, which may allow water to eventually enter through the seams or snap front closure when exposed for extended periods of time in a downpour. 100% nylon 330D with Interior PU waterproof coating Nylon Outer Shell: Waterproof Coating = Level 3 Inner PU Coating: Breath-ability/Permeability = 5,000 Water Pressure Resistance = 10,000 mm self neck tape tear away neck label antique brass eyelets antique brass 6 snap front closure elastic cuffs underarm grommets drawcord closure at bottom opening standard fitLogin to see prices Please Note: Printing Notes:

Use a nylon or plastisol ink with a catalyst (hardener). Certain Poly Inks can work as well. Ask your ink supplier. Keep in mind a catalyst will shorten the shelf life of the ink leaving left over ink unusable as it will harden.

Use tight screens with 200+ mesh count to lay down a little less ink than would be used on tees (tees normally use a more open mesh like a 110). Ink tends to sit on top of the surface of this fabric as opposed to pressing into cotton type fabrics. A harder squeegee can help lay down less ink and help keep cleaner design edges.

Nylon fabric also tends to move more than tees on the printing pallet. Sometimes a jacket clamp is recommended when doing multi-color prints.

Curing time and temperature will vary by ink types used on nylon fabrics. VERY IMPORTANT to cure your ink at the right temperature without burning or shrinking nylon. Nylon fabrics should usually be cured at temperatures under 320. Flash at low temperatures to keep from burning and/or shrinking fabric. (consult ink supplier and test).

Washing the printed sample garment(s) after 24+ hours (so hardener has set) is recommended to make sure you have proper curing and ink adhesion.

*ALWAYS consult your ink supplier for the right ink, cure temperatures, and curing time. Then run your own test sample(s)

Please Note: Printing Notes:

Use a nylon or plastisol ink with a catalyst (hardener). Certain Poly Inks can work as well. Ask your ink supplier. Keep in mind a catalyst will shorten the shelf life of the ink leaving left over ink unusable as it will harden.

Use tight screens with 200+ mesh count to lay down a little less ink than would be used on tees (tees normally use a more open mesh like a 110). Ink tends to sit on top of the surface of this fabric as opposed to pressing into cotton type fabrics. A harder squeegee can help lay down less ink and help keep cleaner design edges.

Nylon fabric also tends to move more than tees on the printing pallet. Sometimes a jacket clamp is recommended when doing multi-color prints.

Curing time and temperature will vary by ink types used on nylon fabrics. VERY IMPORTANT to cure your ink at the right temperature without burning or shrinking nylon. Nylon fabrics should usually be cured at temperatures under 320. Flash at low temperatures to keep from burning and/or shrinking fabric. (consult ink supplier and test).

Washing the printed sample garment(s) after 24+ hours (so hardener has set) is recommended to make sure you have proper curing and ink adhesion.

*ALWAYS consult your ink supplier for the right ink, cure temperatures, and curing time. Then run your own test sample(s) -

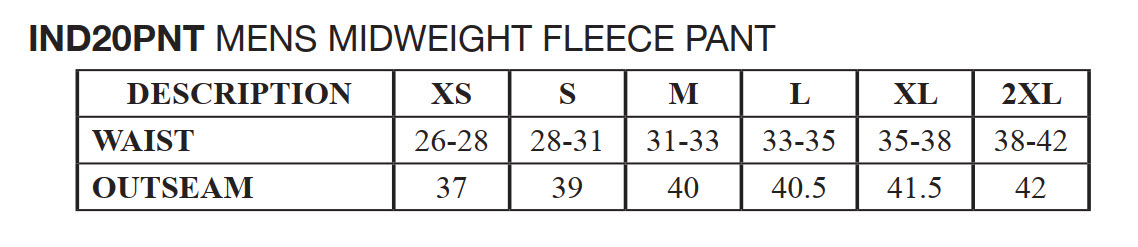

MENS MIDWEIGHT FLEECE PANT

Click here to download Spec Sheet Our Men's Midweight Fleece Pant is made with quality midweight fabric in a relaxed fit. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, elastic waistband with shoestring drawcord, sewn eyelets, sewn fly detail, back pocket, jersey lined hand pockets, and 1x1 ribbing at cuffs in a relaxed fit. 8.5 oz. (280gm) cotton/polyester blend fleece ring spun cotton Solid Colors & Camo: 80% Cotton/20% Polyester with 100% Cotton Face Yarn. Grey Heather: 52% Cotton/48% Polyester elastic waistband with shoestring drawcord 1x1 ribbing at ankle cuffs sewn eyelets sewn fly detail back pocket & Jersey lined hand pockets relaxed fitLogin to see prices Please Note:

• The fabric color of this 8.5oz 3-end Fleece pant is a close match to our IND4000 10oz 3-end Fleece Hoodie. If you are using this pant to color match a sweatshirt as a set, please order samples to see how well they match.

• The heather colors are not made of 100% cotton face yarn. Please do your own testing prior to screen printing.

• When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Our Camo Colorways are a Water Based Print on 100% cotton fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems.

Please Note:

• The fabric color of this 8.5oz 3-end Fleece pant is a close match to our IND4000 10oz 3-end Fleece Hoodie. If you are using this pant to color match a sweatshirt as a set, please order samples to see how well they match.

• The heather colors are not made of 100% cotton face yarn. Please do your own testing prior to screen printing.

• When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Our Camo Colorways are a Water Based Print on 100% cotton fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems. -

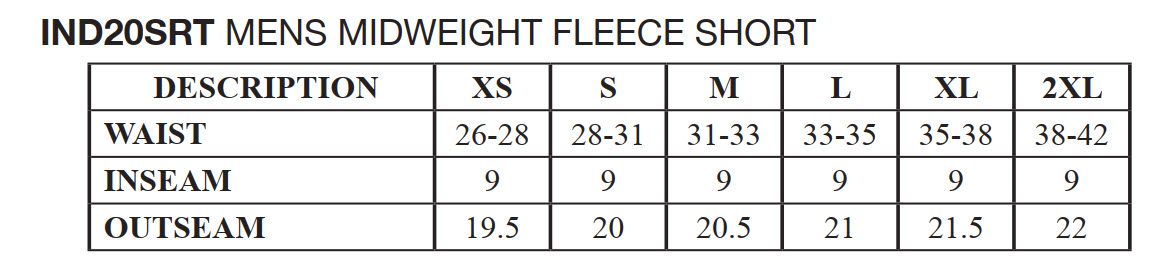

MENS MIDWEIGHT FLEECE SHORT

Our Men's Midweight Fleece Short is made with quality midweight fabric in a relaxed fit. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, elastic waistband with shoestring drawcord, sewn eyelets, sewn fly detail, back pocket, and jersey lined hand pockets in a relaxed fit with tapered knee opening. 8.5 oz. (280gm) cotton/polyester blend fleece with 32 Singles face yarn ring spun cotton Solid Colors & Camo: 80% Cotton/20% Polyester with 100% Cotton Face Yarn. Grey Heather: 52% Cotton/48% Polyester elastic waistband with shoestring drawcord sewn eyelets sewn fly detail back pocket & Jersey lined hand pockets relaxed fit with tapered knee openingLogin to see prices Please Note:

• The fabric color of this 8.5oz 3-end Fleece pant is a close match to our IND4000 10oz 3-end Fleece Hoodie. If you are using this pant to color match a sweatshirt as a set, please order samples to see how well they match.

• The heather colors are not made of 100% cotton face yarn. Please do your own testing prior to screen printing.

• When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Our Camo Colorways are a Water Based Print on 100% cotton fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems.

Please Note:

• The fabric color of this 8.5oz 3-end Fleece pant is a close match to our IND4000 10oz 3-end Fleece Hoodie. If you are using this pant to color match a sweatshirt as a set, please order samples to see how well they match.

• The heather colors are not made of 100% cotton face yarn. Please do your own testing prior to screen printing.

• When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Our Camo Colorways are a Water Based Print on 100% cotton fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems. -

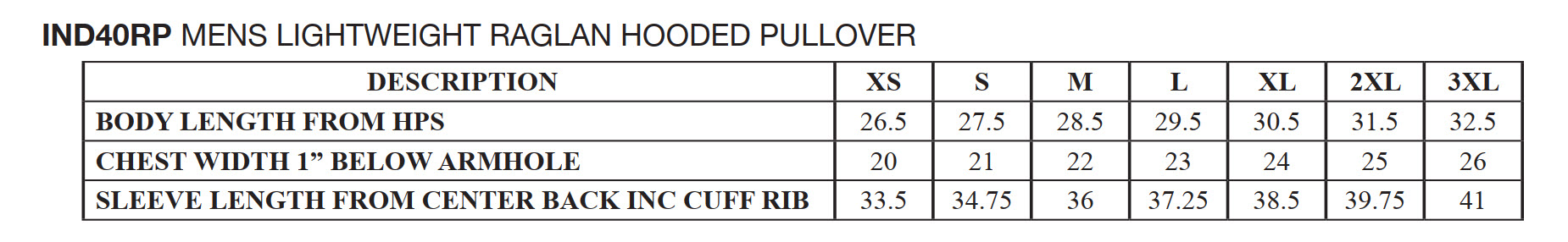

RAGLAN HOODED PULLOVER SWEATSHIRT

Click here to download Spec Sheet Our Men's IND40RP 2-tone raglan hooded pullover are offered in a variety of great color combinations. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with a jersey lined hood, nickel eyelets, flat drawcord and 1x1 ribbing at cuffs and waistband. 7.0 oz (230 gm) 55% cotton/45% polyester blend fleece ring spun cotton raglan sleeves jersey lined hood split stitch double needle sewing front pouch pocket twill neck tape tear away neck label 1x1 ribbing at cuffs and waistband nickel eyelets slim fitLogin to see prices Please note: This style is not made of 100% cotton face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric

Please note: This style is not made of 100% cotton face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric -

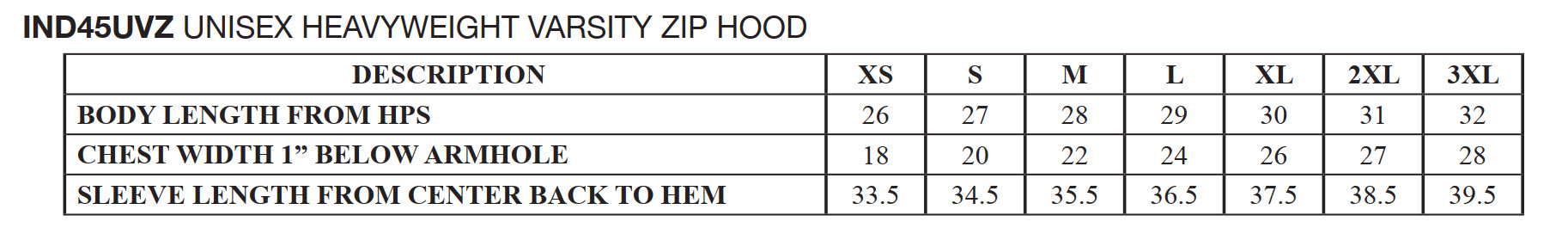

ADULT UNISEX VARSITY ZIP HOOD

Click here to download Spec Sheet Don't get held back this spring by bulky and boxy wool varsity jackets like your grandfather wore. From street to school, this 10 oz. cotton/poly blend earns an A+ with an ultra soft feel, universal unisex fit, and six classic color combos. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with a fleece lined hood, gunmetal eyelets, #5 nylon kissing zipper, and jacquard ribbing at cuffs and waistband. 10oz (330 gm) cotton/polyester blend 3-end fleece. ring spun cotton Solid Colors: 75% Cotton/25% Polyester with 100% Cotton 30 singles face yarn Heather Colors: 52% Cotton/48% Polyester (Charcoal Heather, Gunmetal Heather) fleece lined hood split stitch double needle sewing on all seams twill neck tape tear away neck label 1x1 jacquard ribbing at cuffs and waistband gunmetal eyelets #5 YKK nylon kissing zipper slim unisex fitLogin to see prices Please note: This style is not made of 100% cotton face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

Please note: This style is not made of 100% cotton face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric. -

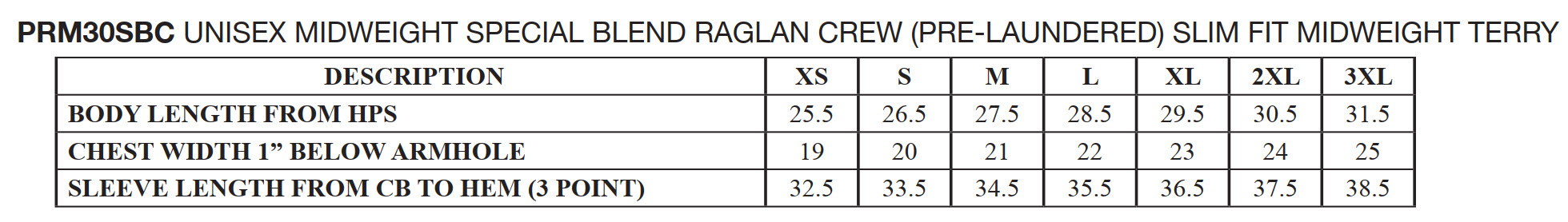

UNISEX SPECIAL BLEND CREW

One touch and you will be hooked on Special Blend fleece! Unmatched in softness, our Unisex Midweight Special Blend Crew has a slim fit in a beautiful selection of available colors. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, raglan sleeves, self fabric side panel inserts, and 1x1 ribbing at cuffs and waistband in a slim unisex fit. 8oz (270 gm) 52% cotton/48% polyester blend ring spun cotton 32 singles cotton/polyester blend face yarn reverse coverstitch sewing twill neck tape tear away neck label 1 x 1 ribbing at neck, cuffs and waistband self fabric side panel inserts slim unisex fitLogin to see prices Please note: Special Blend fabric has a Cotton/Polyester Blend face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Special Blend Camo Colorways are a Water Based Print on a Cotton/Polyester Blend fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems

Please note: Special Blend fabric has a Cotton/Polyester Blend face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Special Blend Camo Colorways are a Water Based Print on a Cotton/Polyester Blend fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems -

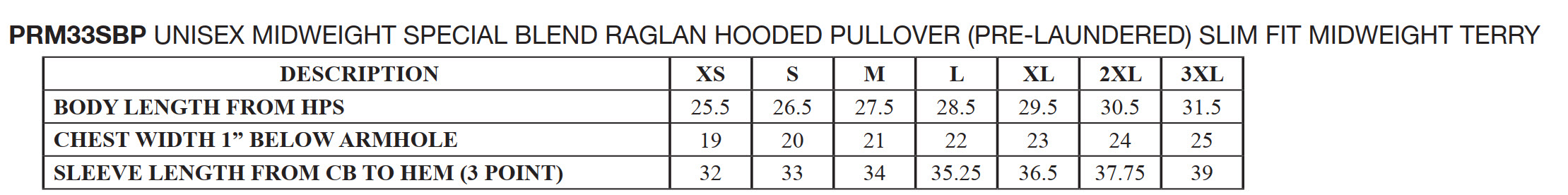

UNISEX SPECIAL BLEND RAGLAN HOODED PULLOVER

Click here to download Spec Sheet One touch and you will be hooked on Special Blend fleece! Unmatched in softness, our Unisex Midweight Special Blend Hooded Pullover has a slim fit in a beautiful selection of available colors. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, raglan sleeves, sewn eyelets, self fabric side panel inserts, and 1x1 ribbing at cuffs and waistband in a slim unisex fit. 8oz (270 gm) 52% cotton/48% polyester blend ring spun cotton 32 singles cotton/polyester blend face yarn reverse coverstitch sewing twill neck tape tear away neck label 1 x 1 ribbing at neck, cuffs and waistband sewn eyelets self fabric side panel inserts slim unisex fitLogin to see prices Please note: Special Blend fabric has a Cotton/Polyester Blend face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Special Blend Camo Colorways are a Water Based Print on a Cotton/Polyester Blend fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems.

Please note: Special Blend fabric has a Cotton/Polyester Blend face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Special Blend Camo Colorways are a Water Based Print on a Cotton/Polyester Blend fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems. -

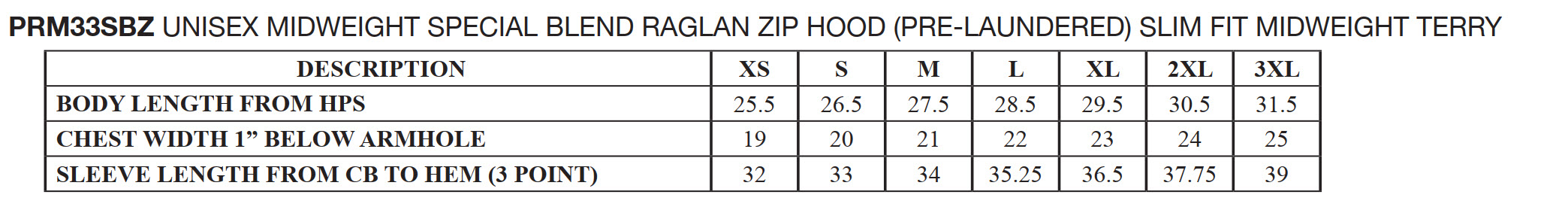

UNISEX SPECIAL BLEND ZIP HOODED SWEATSHIRT

Click here to download Spec Sheet One touch and you will be hooked on Special Blend fleece! Unmatched in softness, our Unisex Midweight Special Blend Zip Hood has a slim fit in a beautiful selection of available colors. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, raglan sleeves, sewn eyelets, #5 antique nickel kissing zipper, self fabric side panel inserts, and 1x1 ribbing at cuffs and waistband in a slim unisex fit. 8oz (270 gm) 52% cotton/48% polyester on blend fleece ring spun cotton 32 singles cotton/polyester blend face yarn raglan sleeves unlined hood reverse coverstitch sewing twill neck tape tear away neck label 1 x 1 ribbing at cuffs and waistband sewn eyelets self fabric side panel inserts YKK antique nickel kissing zipper slim unisex fitLogin to see prices Please note: Special Blend fabric has a Cotton/Polyester Blend face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Special Blend Camo Colorways are a Water Based Print on a Cotton/Polyester Blend fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems

Please note: Special Blend fabric has a Cotton/Polyester Blend face yarn. Please do your own testing prior to screen printing. This is not a discharge friendly fabric.

When printing on our Camo Colorways it is important that the garment DOES NOT reach 320 Degrees when flashing or drying.

Special Blend Camo Colorways are a Water Based Print on a Cotton/Polyester Blend fabric surface.

At 320 degrees you risk ink migration to your print.

To be really safe some printers use a Poly Blocker base, and low temperature curing inks to stay away from 320 degrees.

300 degrees or lower is a safer temperature to avoid ink migration problems -

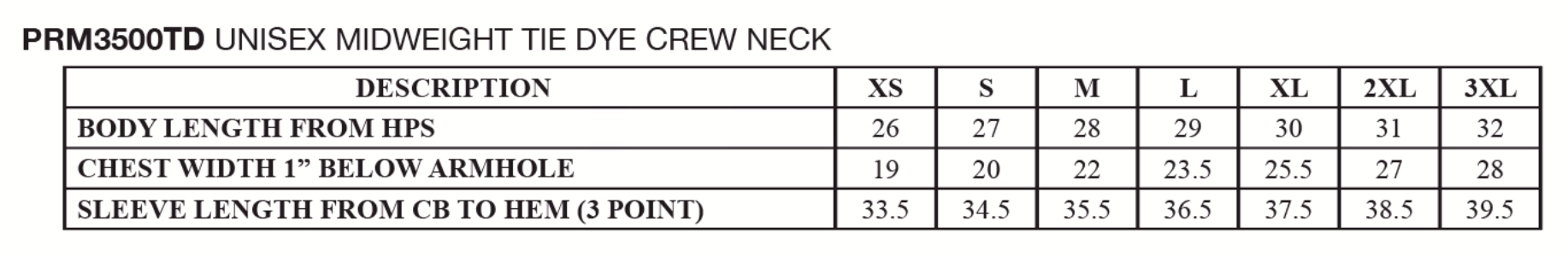

UNISEX MIDWEIGHT TIE DYED CREW NECK

Login to see pricesClick here to download Spec Sheet Our Unisex Midweight Tie Dyed Crew has individual and unique character we accomplish during our full garment tie dying process. Made with ultra soft cotton/polyester blend fleece in an assortment of amazing colors, these garments are as comfortable as they are eye catching. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, twill neck tape, and 1x1 ribbing at cuffs and waistband with a standard unisex fit. 9oz (300 gm) 80% cotton/20% polyester blend ring spun cotton 100% cotton 30 singles face yarn split stitch double needle sewing on all seams twill neck tape 1 x 1 ribbing at cuffs and waistband Standard fitPlease note: The tie-dyeing process gives each garment unique character. Please allow for slight color variation in production and washing.- Care Instructions: Due to the nature of tie dye, loose pigments may remain on the surface of the garments. We therefore strongly recommend washing these garments only with like-colored garments, as some of the tie dyes may stain light or white colored garments in the wash cycle.

- Washing the garments in cold water will reduce the possibility of staining.

- *PFD Note: Our PRM4500 & PRM3500 Prepare For Dye sweatshirts are not 100% Cotton. They are a 3-End Knit with 100% cotton Face Yarn, 100% Polyester Middle Yarn, and 80% Cotton/20% Poly back yarn. We chose this blend to achieve some stretch, and an ultra-soft feel for our tie dye that isn’t found in 100% Cotton. Please do your own testing prior to bulk production. Tie Dyes, Pigment Dyes, and other unique dyes/washes work best on this garment. The sewing thread on this PFD Garment is a polyester core cotton sheath thread. We use this to achieve the strength of polyester thread with the dye capabilities of Cotton thread.

-

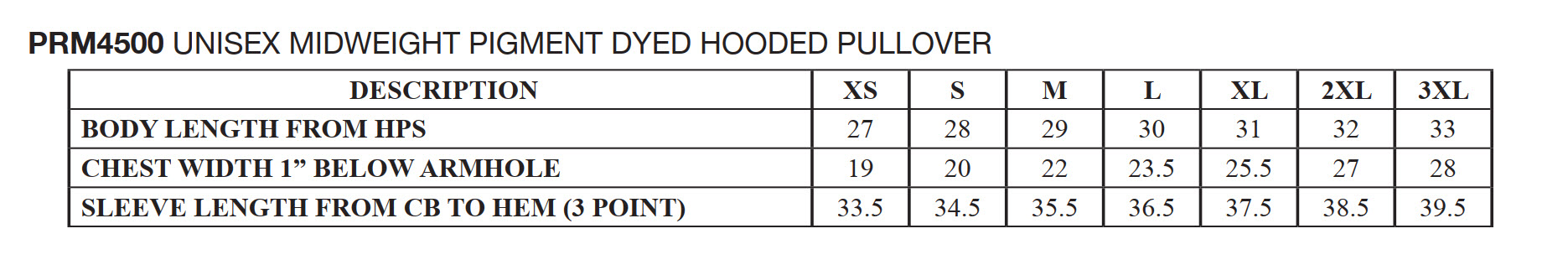

UNISEX MIDWEIGHT PIGMENT DYED HOODED PULLOVER

Click here to download Spec Sheet Our Unisex Midweight Pigment Dyed Hooded Pullover has individual and unique vintage character we accomplish during our full garment dying process. Made with ultra soft cotton/polyester blend fleece in an assortment of amazing colors, these garments are as comfortable as they are eye catching. We use premium ring-spun cotton to achieve a smooth and stable fabric surface for printing. Completed with our quality construction, jersey lined hood, sewn eyelets, and 1x1 ribbing at cuffs and waistband in a standard unisex fit. 9oz (300 gm) 80% cotton/20% polyester blend ring spun cotton 100% cotton 30 singles face yarn jersey lined hood split stitch double needle sewing on all seams twill neck tape 1 x 1 ribbing at cuffs and waistband sewn eyelets standard fitLogin to see prices Please note:

The pigment-dyeing process gives each garment unique character. Please allow for slight color variation in production and washing

Care Instructions: Due to the nature of pigment dye, loose pigments may remain on the surface of the garments. We therefore strongly recommend washing these garments only with like-colored garments, as some of the pigment dyes may stain light or white colored garments in the wash cycle.

Washing the garments in cold water will reduce the possibility of staining.

*PFD Note: Our Prepare For Dye sweatshirts, fleece pants, and fleece shorts are not 100% Cotton. They are a 3-End Knit with 100% cotton Face Yarn, 100% Polyester Middle Yarn, and 80% Cotton/20% Poly back yarn. We chose this blend to achieve some stretch, and an ultra-soft feel for our pigment dye that isn’t found in 100% Cotton. Please do your own testing prior to bulk production. Pigment Dyes, Tie Dyes and other unique dyes/washes work best on these garments. The sewing thread on this PFD Garment is a polyester core cotton sheath thread. We use this to achieve the strength of polyester thread with the dye capabilities of Cotton thread. Although this thread takes dye better than Polyester thread, Dark Reactive dyes and Overdyes are not recommended because the thread doesn’t take dye as well as 100% Cotton. Tie dyes, Pigment Dyes, Mineral Washes, dip dyes etc work best. The Poly Core/Cotton Sheathe thread is very strong so the decreased amount of fallout from broken threads when dyeing is the major benefit, this thread is very strong.

The "PFD Prepared for Dye" Garment is the raw garment we use to garment dye. You can wear it as is, or dye it yourself. Keep in mind it will have a slightly larger fit because it has not been garment dyed yet. After a garment dye or wash, the PFD garment will shrink to match the Pigment Dyed spec.

Please note:

The pigment-dyeing process gives each garment unique character. Please allow for slight color variation in production and washing

Care Instructions: Due to the nature of pigment dye, loose pigments may remain on the surface of the garments. We therefore strongly recommend washing these garments only with like-colored garments, as some of the pigment dyes may stain light or white colored garments in the wash cycle.

Washing the garments in cold water will reduce the possibility of staining.

*PFD Note: Our Prepare For Dye sweatshirts, fleece pants, and fleece shorts are not 100% Cotton. They are a 3-End Knit with 100% cotton Face Yarn, 100% Polyester Middle Yarn, and 80% Cotton/20% Poly back yarn. We chose this blend to achieve some stretch, and an ultra-soft feel for our pigment dye that isn’t found in 100% Cotton. Please do your own testing prior to bulk production. Pigment Dyes, Tie Dyes and other unique dyes/washes work best on these garments. The sewing thread on this PFD Garment is a polyester core cotton sheath thread. We use this to achieve the strength of polyester thread with the dye capabilities of Cotton thread. Although this thread takes dye better than Polyester thread, Dark Reactive dyes and Overdyes are not recommended because the thread doesn’t take dye as well as 100% Cotton. Tie dyes, Pigment Dyes, Mineral Washes, dip dyes etc work best. The Poly Core/Cotton Sheathe thread is very strong so the decreased amount of fallout from broken threads when dyeing is the major benefit, this thread is very strong.

The "PFD Prepared for Dye" Garment is the raw garment we use to garment dye. You can wear it as is, or dye it yourself. Keep in mind it will have a slightly larger fit because it has not been garment dyed yet. After a garment dye or wash, the PFD garment will shrink to match the Pigment Dyed spec.